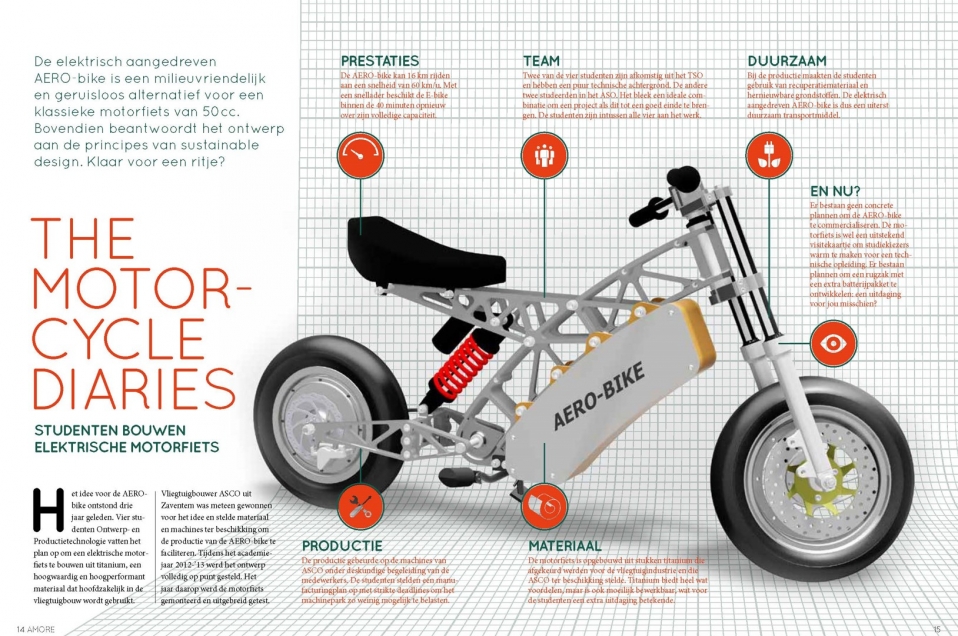

AEROBIKE mo(to)bility of the future

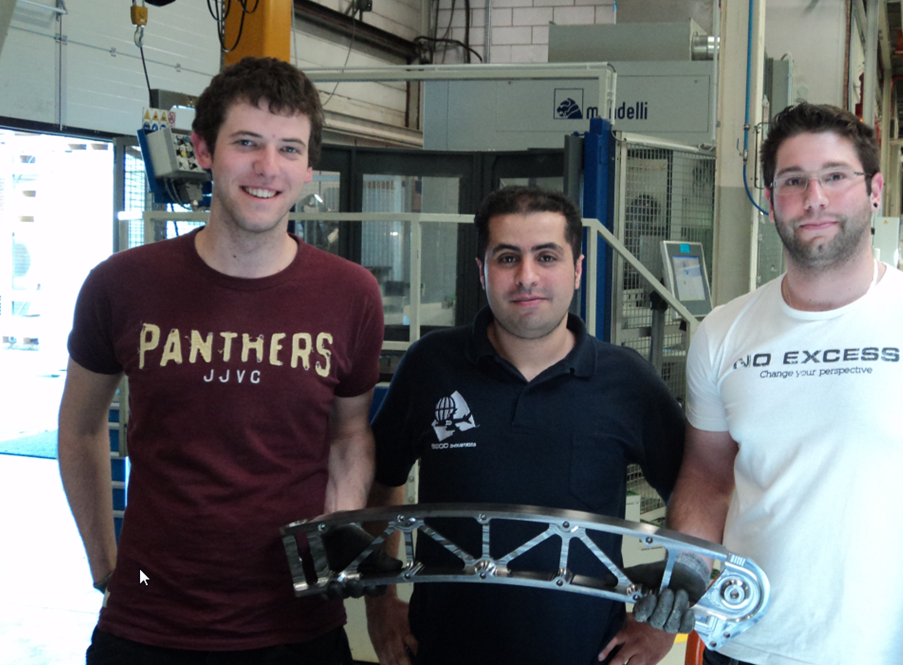

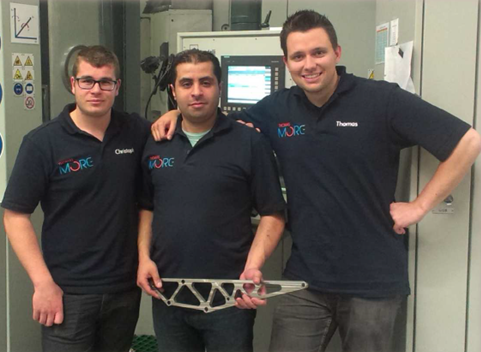

An unique electric bike was developed by four students, professor of Thomas More and two employees of ASCO Industries.

The project was foreseen for two students during two school years.

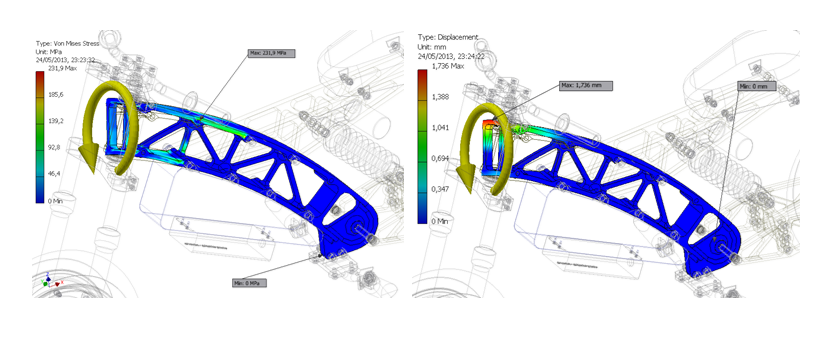

During the development of the bike, the choice of material changed from aluminium to titanium. Due to this a better design was developed while remaining within specification. This also makes the bike unique and the first and only in the world.

Bigger challenge, machining and design change but the whole FEA needed to match titanium characteristics.

Important tool such as an industrilization plan is used to plan and organize the project. Communication is very important and the tool really helped between two years.

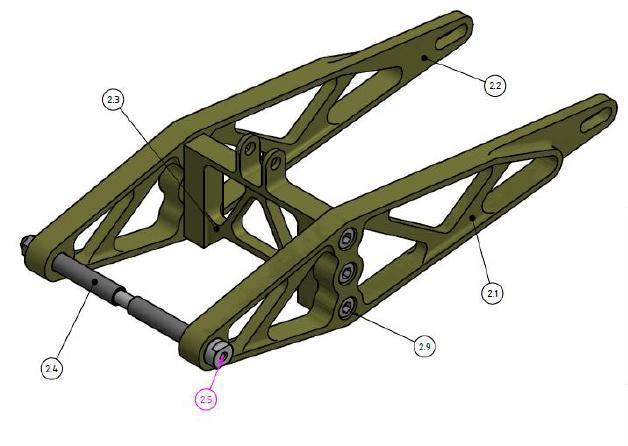

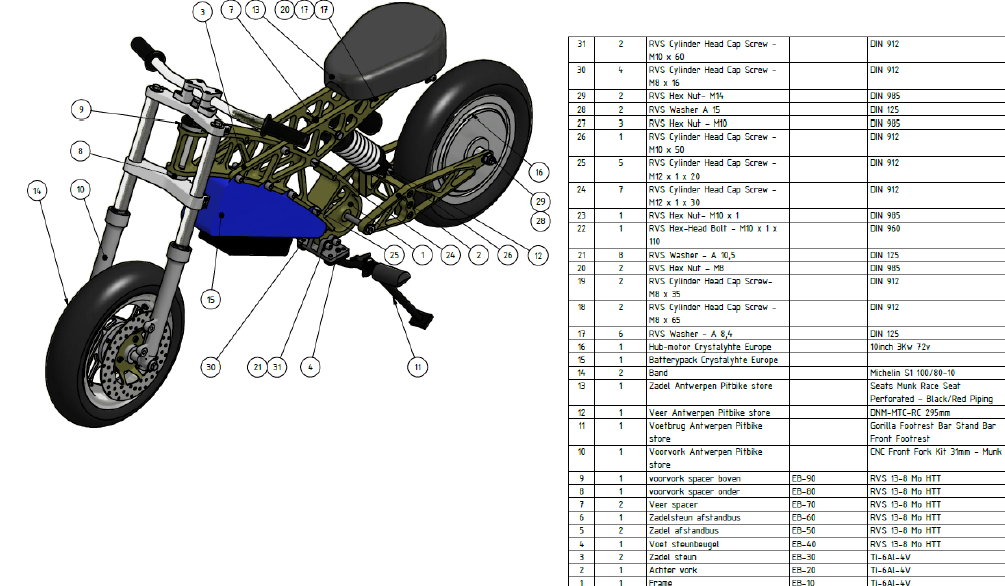

Project included developing, manufacture, special processes, electronics, project management and so much more.

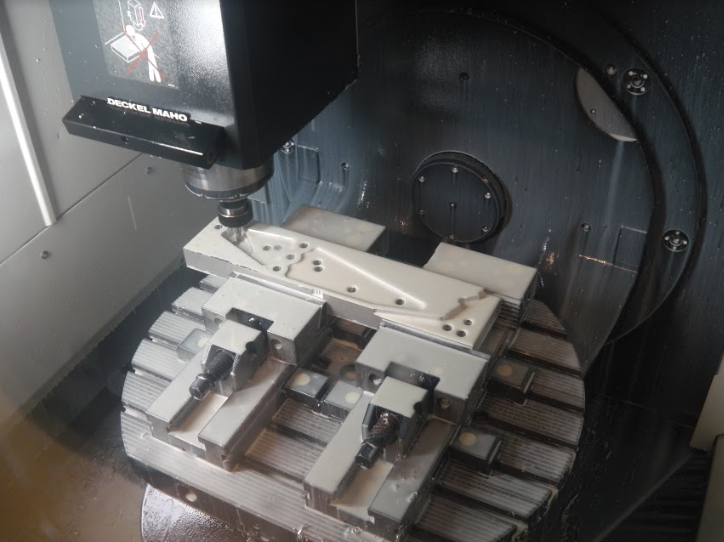

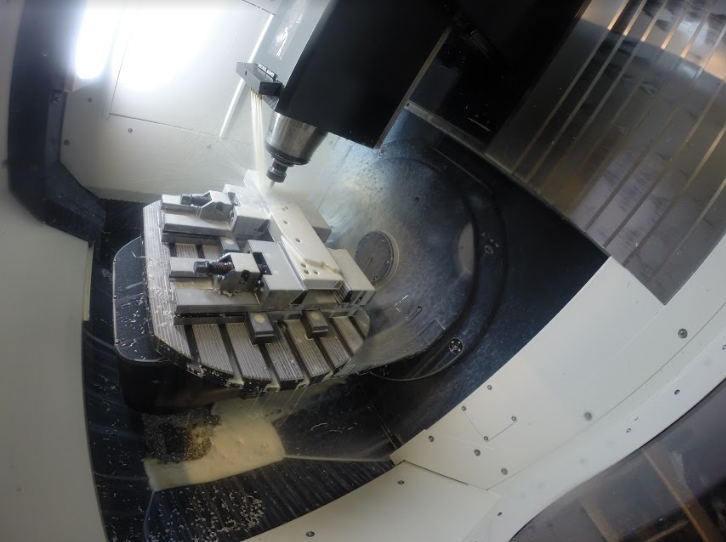

Surface treatement and machining of the larger components been done @ ASCO on a professional 5-Axis CNC machine. The smaller components been machinined @ Thomas More.

Choise of titanium, surface treatement used in aeropace, programmable electronics made the name change from E-Bike to AEROBIKE.

The AEROBIKE contribute a better environment due lower emission and help making the world better.

Another reason that full deals the Aerospace Machining Academy philosophy.

This project has inspired so many people to discover the technical challenges. Everyone who has driven with it would like to have one. The Aerobike should have a future.

Some requirements, specifications and figures.

150 kg rider weight limit.

Safety factor used in aerospace.

Match aerospace manufacture requirements.

Aerospace surface treatement must be performed

CMM measuring to meet standards.

First Time Right methodologies

Smallest tolerance –> 2µ

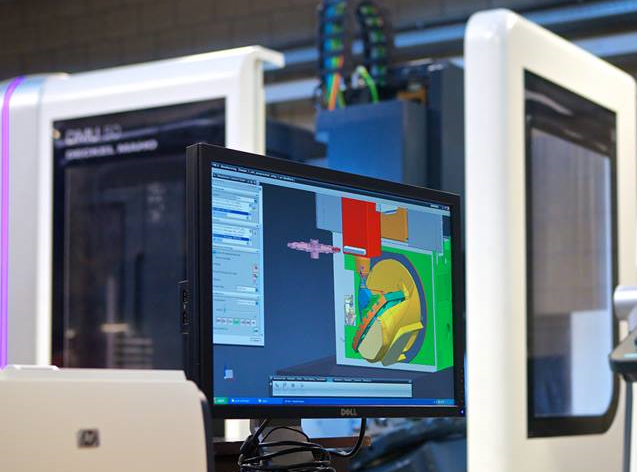

CAE/CAD/CAM

Design to cost

Titanium 6al-4v

Build to spec.

industrialization plan

5-Axis CNC Milling

100km/h limited to 60km/h for security reasons

Range 16Km full speed at full load

20 kWh battery pack

3 kW motor